Have you ever wished you had more time to perfect your design? Too often, budgets and deadlines push us to move fast and settle on work that’s just “good enough.” Recent enhancements in Creo empower product designers with tools that help to accelerate the design process and ensure that a design concept will work from early in the design phase.

Creo Simulation tools provide guidance on the thousands of decisions you make throughout the development process, improving quality, reducing time to market, and saving you money, while Creo Multibody Design capabilities dramatically simplify part design, greatly improving modelling efficiency. LEAP recently ran webinars on each of these core features of Creo which are now available on-demand below and we have scheduled the final webinar of the series on Advanced Assembly Design for December 7th 2021. Learn more about these advanced capabilities of Creo and register for the upcoming webinar below.

Reworking Your Workflow for Better Product Design

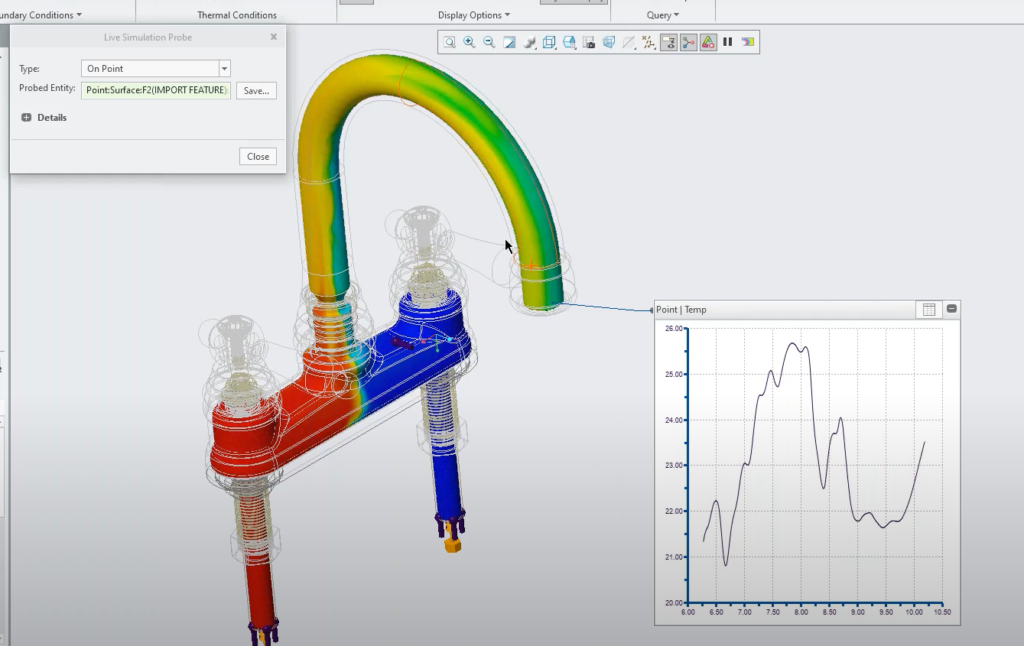

Traditionally, design engineers and analysts worked in tandem to produce quality products, but the traditional approach has also meant an increase in time to market and the abandoning of potential solutions that never get tested out. Rethinking design and incorporating a few workflow changes can enable design engineers to iterate faster and pass on their best work to analysts with greater confidence. But how do we get there?

Ben Muston, Application Engineer at LEAP Australia recently ran a webinar entitled Reworking Your Workflow for Better Product Design with Creo Simulation Live where he explained how the adoption of simulation early in the design process can accelerate time to market and improve product quality. You can read the summary of this presentation and watch clips from this webinar on our product design software blog.

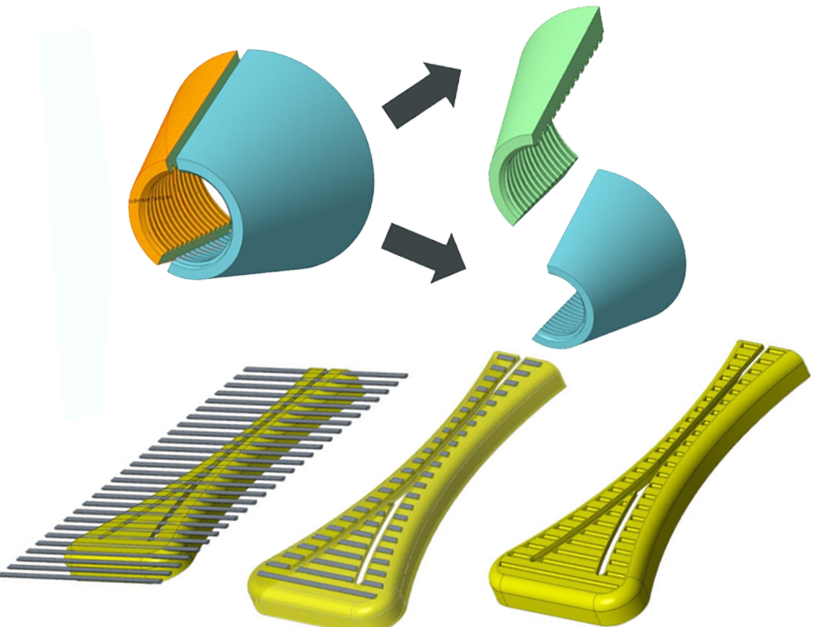

Multibody: More Possibilities for Your Parts

Every seat of Creo now includes multibody design capabilities which can dramatically simplify part design. These capabilities can greatly improve modelling efficiency when you wish to:

- Design interdependencies between two parts.

- Split a solid part into multiple parts.

- Use multiple materials in a single part.

Taju Joseph, Application Engineer at LEAP Australia recently presented a webinar looking at the surprising ways Multibody Design can help you develop higher quality products faster. We have summarised this webinar and included clips of the presentation. Read the article to learn how you can start working smarter with Creo Multibody Design today. Read more

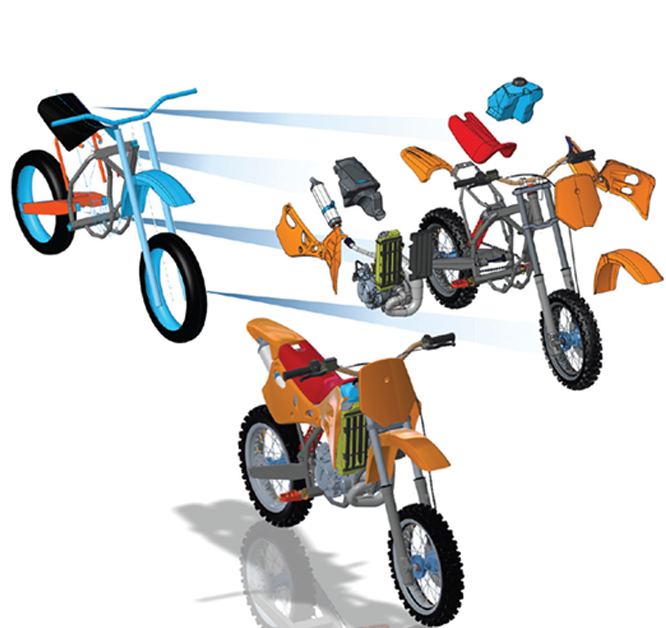

Advanced Assembly Design with Creo

Any time a team works with complex assemblies, they risk miscommunications, gaps, and overlap. The result? Errors and rework. That’s why Creo develops powerful capabilities for managing all of your most complex assemblies. Our recent webinar included demonstrations of:

- Top-down design

- Product Structure

- Skeletons

- Data sharing

- Notebooks

- Concurrent engineering

Watch the recording of this webinar presented by Taju Joseph, Application Engineer at LEAP Australia to learn more about the advanced assembly design capabilities within Creo and how they can help improve the quality of your models. Read the summary and watch the recording here.