Ansys AIM Capabilities

Guided Simulation Workflows

AIM’s guided simulation workflows and highly intuitive user interface streamline the setup and execution of engineering simulation, making it easy to apply simulation early in the design process, when it can be used for critical design decisions. AIM’s templates guide you through the entire simulation process and automate many of the routine steps, enabling you to focus on the engineering. The visual cues and guides included in AIM user interface help you to quickly identify and navigate to model inputs that require attention. You will spend less time learning — or, for infrequent users, relearning— and operating the software, making you more productive.

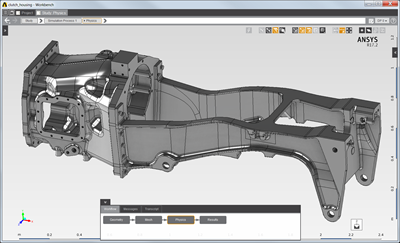

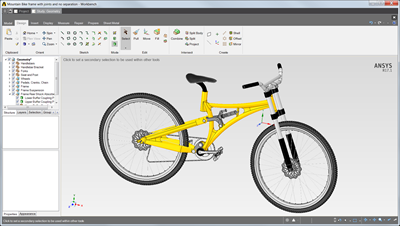

Integrated Geometry Modeling

AIM integrates Ansys SpaceClaim technology to give you the best geometry modeling tools in the industry. SpaceClaim enables you to rapidly create, edit and repair geometry and evaluate design changes. You can import and edit geometry from any 3-D CAD system and quickly prepare it for engineering simulation; easily suppress unwanted parts; simplify geometry by removing unnecessary details, such as small fillets or faces, to simplify the generation of a high quality mesh; rapidly repair dirty geometry to create watertight solids; and easily extract fluid volumes from complex solid assemblies. AIM also lets you evaluate multiple design variations by setting adjustable parameters on any geometry, or enlist the built-in optimization engine to find the best design automatically.

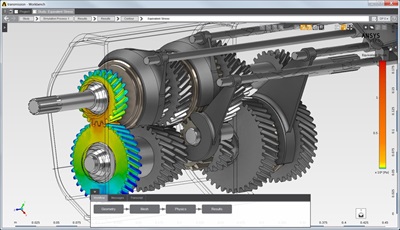

Proven Simulation Technology

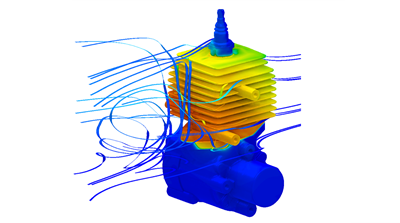

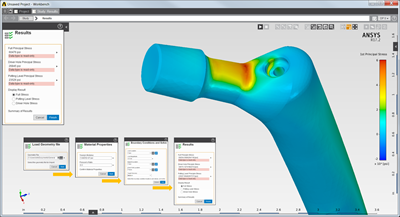

AIM is based on trusted Ansys technology for all the steps of upfront simulation — model setup, meshing and physics solution — enabling reliable and accurate fluid, structural, thermal, electromagnetic and multiphysics simulations.

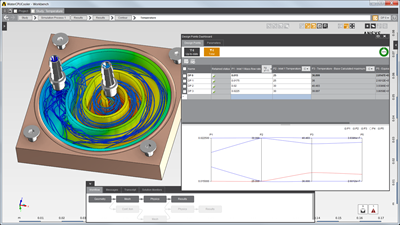

Fluid flow: Accurately simulate key fluid flow problems such as reducing pressure drop, calculating lift and drag coefficients, evaluating fluid loads and predicting flow behavior.

Static stress: Analyze static deflections and stresses for complex parts and assemblies using static stress analysis, including nonlinear contact, structural joints and large deflections.

Modal analysis: Determine, with proven modal analysis, the natural frequencies and vibration characteristics of your product designs to fully understand product longevity and durability.

Electromagnetics: Rapidly simulate static magnetic fields and current conduction to accurately evaluate the electromagnetic performance of your designs.

Thermal: Ensure your designs perform properly within their expected temperature ranges by accurately simulating thermal performance.

Polymer extrusion: Reduce trial-and-error iterations and quickly troubleshoot unexpected problems when simulating polymer extrusion processes and evaluating die designs.

Robust Design Optimisation

AIM’s powerful design exploration and optimization capabilities help you to make informed design decisions and optimize your product designs. AIM includes Ansys DesignXplorer technology, so you can explore your design space rapidly and thoroughly, and automatically optimize your product designs. By varying parameters from CAD, material properties, boundary conditions and simulation results, you can quickly set up and evaluate multiple design variations to drive design of experiments, goal-driven optimization and Six Sigma analysis.

Flexible Custom Applications

With AIM’s customization capabilities, you can incorporate your company’s best engineering practices into your simulation process to ensure consistency and accuracy within your organization. AIM includes journaling and scripting based on Python, which enables you to record, customize and replay your simulation. Any simulation can be used as the basis for a replayable user-defined template, and custom physics objects and loads can be used to tailor the simulation definition to specific processes. AIM’s automation and customization capabilities are particularly useful for creating products that must adhere to safety or manufacturing standards.

Interoperability for Engineering Collaboration

AIM uses the same proven Ansys solver technology as Ansys CFD and Ansys Mechanical, so you can trust your results. Design engineers and simulation analysts can work closely together to troubleshoot problems or perform deeper investigations because both use the same Ansys flagship products. Overall, AIM brings Ansys solver technology to design engineers through easy-to-use, guided workflows and makes it simple for them — or the analysts they collaborate with — to overcome challenges using AIM model data.